What will you print today?

Keep every detail under control with the right products and expert technical support.

PRINTING PRODUCTS

INKS

INKS

VARNISHES

VARNISHES

OTHER PRODUCTS

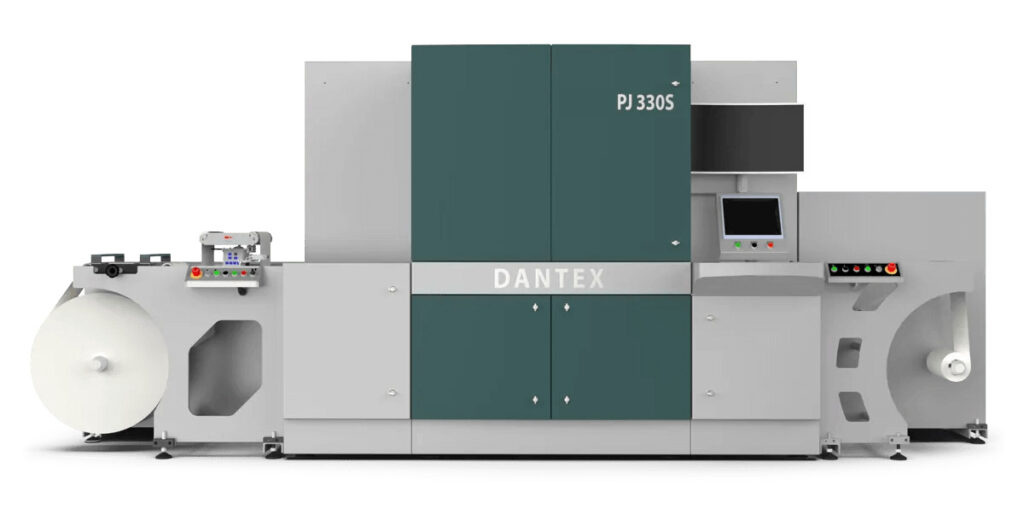

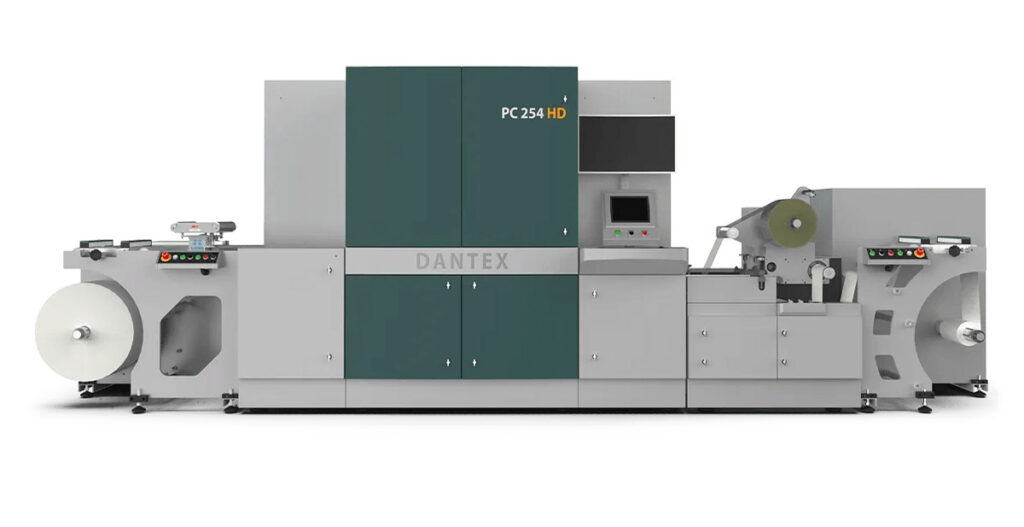

Official Dantex distributors

Dantex is at the service of the label and packaging industry for 50 years and has always been in the technical innovation to meet the specific needs of the market. Dantex is a key supplier for the industry supported by the excellence of its product portfolio competence to meet the changing needs and technologies of the label and packaging market.

The T&K Services

The T&K Services

The Lastest News From The Printing Industry

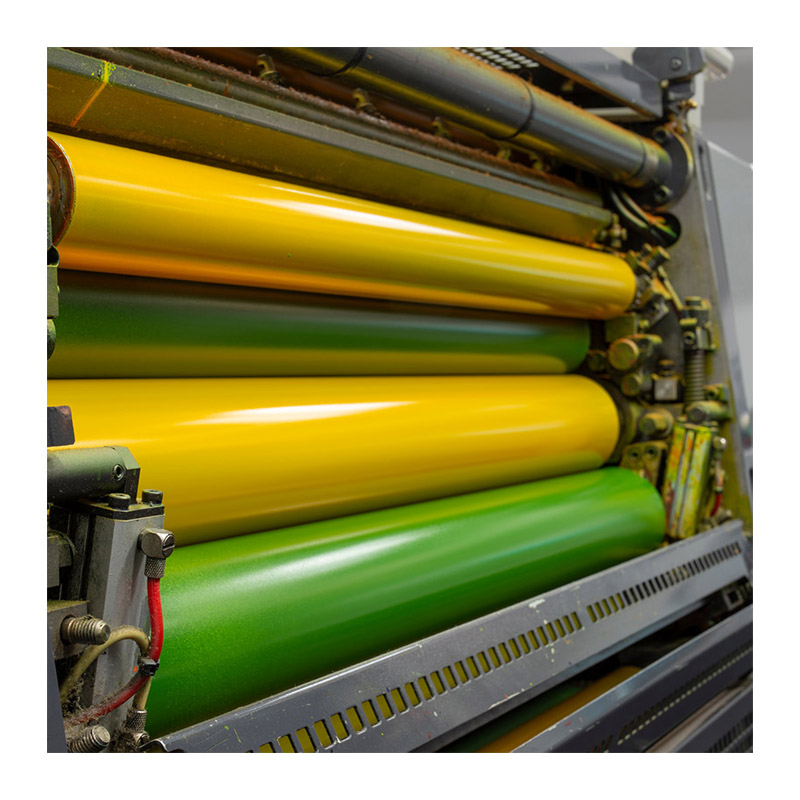

La sostituzione dei rulli e la ri-gommatura non saranno più un problema

2023 is just started, what better time to do a rollers check up and face the new year with serenity?

With our service 𝗥𝗢𝗟𝗟 𝗣𝗔𝗥𝗞 & 𝗚𝗢 we offer a free consultation and we value the current rollers condictions installed on your systems.

To know more contact us at this e-mail address: info@tandk.it

Roll park & go

Roll park & go is the new service T&K available for all the #rollers of rotary and semi-rotary #offset machines.

Our skilled technicians will take care of the disassembly of the rollers and worn mutes and installation of the new ones. A process performed in totally autonomy, safety and speed.

Afer having replaced and collected your rollers we will recondition and regummed them, and then we will store them at our stockrooms waiting for future replacements at your machines, for prompt deilvery.

Choosing riconditioned rollers allows to:

· Save on the final cost

· Avoid long waitings between the order and the delivery from the producer

· Avoid wastes of raw materials

· Reduce pollution

For more info: info@tandk.it

Taga tour, the event dedicated to the UV printing arrives in Turin

The TAGA Tour, the itinerant event dedicated to the UV printing, continous with his tour.

On February 2nd it will be in Turin to host its third stop, at the ISS BODONI PARAVIA at Via Ponchielli 56, 10154 Turin.

Along with TAGA Italia, some of the companies that have contributed at the drafting of TAGA’S documents will alternate to provide with clear and shared information about equipments, specific products, auxiliaries, machines and potential issues.

The enrollment is free.

To enroll: https://bit.ly/3wLPFOh

Plan of the day: https://lnkd.in/emUkxaAf

For more info: info@taga.it

Do you have any questions?

To view all the questions click on the following link

1. Try to reduce the quantity of ink on the rollers through the UCR configuration during the preprinting step. Replace the ink with a higher coloring strenght one.

2. Try to reduce the quantity of dampening solution until the plate takes strength (“dry”). Check the adjustments of the rollers in the machine. Check the quantity and dilution of the dampening.

3. Reduce the temperature down to the value recommended by the machine manufacturer.

4. Replace with an ink that has the specific features for high speed.

1. Make sure the mix level of the dampening solution and the conductivity are in line with the suggested parameters.

2. Rinse properly all the plates after cleaning them.

2. Rinse properly all the plates after cleaning them.

4. Wash the plate completely; prepare a new plate if necessary.

5. Rimove the arabic gum with warm water. Make sure the thickness is going to be reduced in the future, both in the manual application and the automatic one (developer).

1. Adjust the pliers correctly.

2. Adjust the balance water/ink trying to reduce the quantity of water down to the low point. Use a paper quality that doesn’t fan out.

3. Fix the plate.

4. Retire the rubber based on the recommended setting; check the coating or replace everything if necessary.

WHO WE ARE

CONTACT US

Legal seat: Via Canonica 1,

20154 Milano

Tel.: +39 (02) 37920620

Fax: +39 (02) 39304121

info@tandk.it